Introduction

In the fast-moving industries of home care and personal care, manufacturers continually face challenges arising from volatile raw material prices. Recent significant fluctuations in critical ingredients like Sodium Laureth Sulfate (SLES) have underscored how sensitive the market can be. Stable pricing is crucial not only for maintaining profitability but also for competitive positioning. In this article, we will explore the underlying causes of raw material price volatility, examine real-world impacts using SLES as a case study, and provide actionable strategies to mitigate risks.

Understanding the Causes of Raw Material Price Volatility

Global Economic Factors

The global economic landscape significantly affects raw material pricing. Trade tensions, such as the ongoing trade disputes between major economies like China and the U.S., introduce tariffs and trade barriers that escalate production and procurement costs. Additionally, global events such as the COVID-19 pandemic have disrupted supply chains, leading to unprecedented price spikes and supply shortages.

Raw Material Supply Dynamics

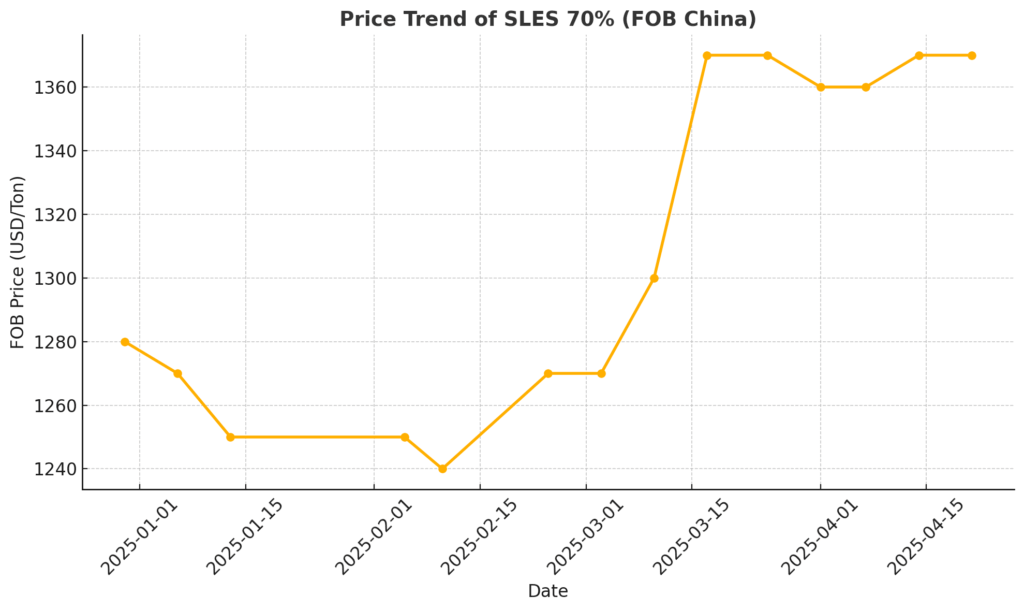

Ingredients like SLES heavily depend on feedstocks derived from crude oil or palm kernel oil, whose prices are highly sensitive to geopolitical events, supply-demand balances, and extraction capacities. Any disruptions, whether due to natural disasters, political instability, or technical production issues, can drastically influence pricing.

Regulatory Changes and Environmental Policies

Increasingly stringent environmental regulations worldwide, particularly concerning sustainable sourcing and production processes, have elevated operational costs. Manufacturers face added expenses to comply with such policies, inevitably transferring costs along the supply chain.Case Study: Recent Price Surge of Sodium Laureth Sulfate (SLES)

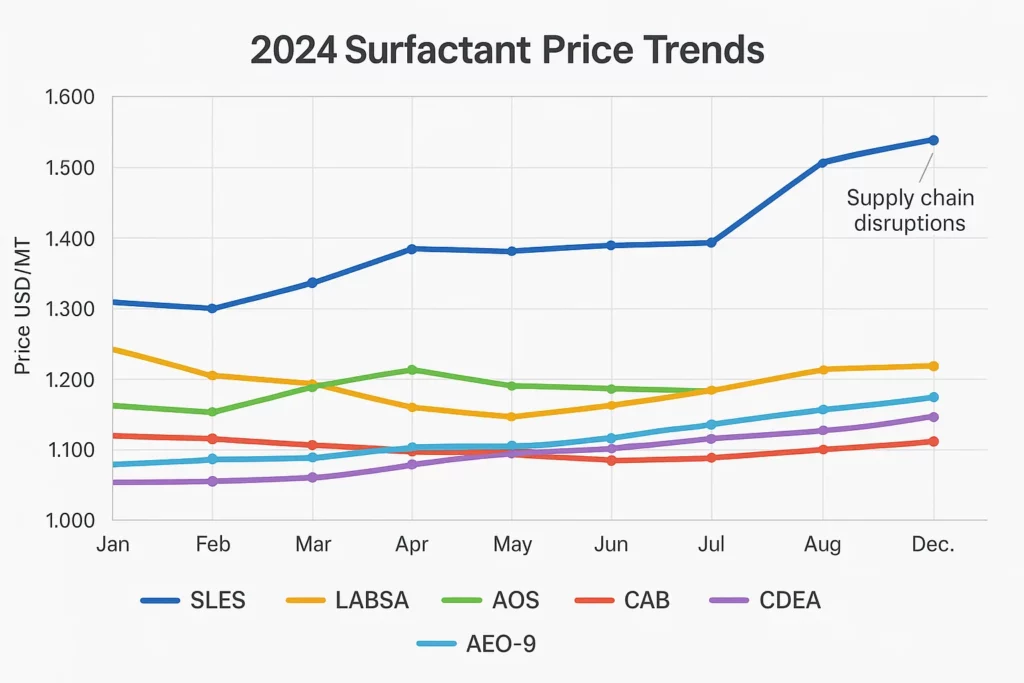

Recent months have witnessed remarkable volatility in SLES pricing, largely attributable to escalating costs of palm oil and palm kernel oil, and petroleum-derived ethylene oxide, the main precursors of SLES. Additionally, limited manufacturing capacities and temporary production halts due to environmental compliance audits have compounded these price escalations. Consequently, manufacturers of shampoos, detergents, and other personal and home care products have experienced substantial operational and financial pressures.Impact of Price Volatility on Manufacturers

Operational Challenges

Frequent price shifts create difficulties in accurately forecasting budgets, which complicates financial planning and inventory management. Increased raw material costs squeeze profit margins, challenging manufacturers to maintain consistent product quality while controlling expenses.

Customer Relationships

Rapid and unpredictable price changes strain relationships with customers. Manufacturers must manage customer expectations carefully, clearly communicating the reasons behind price increases. Failure to navigate these conversations effectively can risk customer loyalty and trust.

Competitiveness

In volatile markets, maintaining competitive pricing becomes increasingly challenging. Sudden price increases of essential raw materials like SLES may force manufacturers to absorb costs temporarily or risk losing market share by raising prices. This volatility can alter competitive dynamics significantly, favoring more agile businesses.

Practical Strategies for Mitigating Price Volatility

Diversifying Supplier Base

One of the most effective strategies for manufacturers to mitigate volatility risks is supplier diversification. Establishing relationships with multiple suppliers across different geographical regions ensures a steady raw material supply, reducing dependency and exposure to localized disruptions.

Strategic Stock Management

Inventory management strategies like strategic inventory buffering or the just-in-time (JIT) approach can help. While JIT reduces holding costs, strategic stockpiling may safeguard against abrupt price increases. Manufacturers must carefully evaluate the costs associated with each strategy to strike a balance between liquidity and risk management.

Flexible Formulation and Ingredient Substitution

Developing versatile formulations that allow ingredient substitutions can significantly mitigate risks. For example, manufacturers can partially replace SLES with alternative surfactants like Alpha Olefin Sulphonate(AOS), C8-14 Alkyl Polyglycoside(APG), or Cocamidopropyl Betaine(CAB) during price spikes, minimizing the impact on production costs without sacrificing quality.

Long-term Contracting and Hedging Approaches

Entering into long-term contracts with suppliers locks in prices, providing stability and predictability. Additionally, exploring financial instruments like hedging can protect businesses against adverse price movements, though this requires detailed market understanding and careful planning.

Leveraging Industry Intelligence and Analytics

Advanced predictive analytics tools help manufacturers anticipate market fluctuations. Regular engagement with industry intelligence platforms and trade associations provides valuable insights, allowing businesses to proactively manage their procurement strategies and mitigate financial risks.

Yeser Chemicals’ Role in Supporting Customers Amid Volatility

At Yeser Chemicals, we recognize the significant challenges our customers face amid raw material price volatility. Our proactive approach includes extensive global sourcing networks, enabling us to offer reliable alternative supplies rapidly. Furthermore, our robust formulation and technical support assist clients in adapting swiftly to ingredient substitutions without compromising product performance. Yeser Chemicals is committed to providing timely market insights and advisory services, ensuring our clients remain agile and competitive despite fluctuating market conditions.

Long-Term Approaches for Enhanced Resilience

Sustainable Supply Chain Practices

Sustainable sourcing and ethical procurement significantly mitigate long-term risks. Developing sustainability-oriented supply chains reduces exposure to regulatory risks and price shocks related to environmentally impactful raw materials.

Innovation and R&D Initiatives

Investing in innovation and developing new, eco-friendly ingredients not only aligns with consumer demand but also reduces dependency on volatile commodities. Yeser Chemicals prioritizes extensive research and development initiatives to provide sustainable and resilient ingredient options.

Collaboration and Industry Partnerships

Building strategic partnerships with suppliers, research institutions, and even competitors can foster greater resilience. Collaborative efforts facilitate knowledge sharing, risk distribution, and joint problem-solving, enabling businesses to better withstand market volatility.

Conclusion

Effectively managing raw material price volatility requires an integrated approach encompassing diversification, strategic inventory practices, flexible formulations, long-term contracting, and leveraging industry intelligence. By adopting these strategies, manufacturers can navigate turbulent market conditions confidently and sustainably.

Yeser Chemicals remains dedicated to supporting customers through comprehensive solutions designed to manage volatility, ensuring continuity and growth in an ever-evolving market landscape.

Call to Action

For customized advice, reliable sourcing solutions, or assistance with flexible and robust formulations, reach out to our experts at Yeser Chemicals today. Together, we can effectively navigate market uncertainties and secure your business’s resilience.