Introduction

In the realm of industrial manufacturing, evolution is not just a choice; it’s a necessity. Yeser Chemicals, a name long associated with the supply of high-quality raw materials, is embarking on a remarkable journey, transcending its traditional boundaries.

My name is Bryant Chen, the marketing director at Yeser Chemicals. My experience in establishing DAFA SOAP AND DETERGENT MANUFACTURING PLC in Ethiopia and running it as a successful business has been instrumental in guiding this new direction. Here, I share our journey and the rationale behind our expansion into comprehensive turnkey production solutions.

A New Direction

The decision to expand our business into production-line turnkey solutions was born from a strategic vision to offer more comprehensive support to our clients. This new venture represented a significant shift from being a mere raw material supplier to becoming an end-to-end solutions provider.

Learned from my real-world experience, I strongly believe that a high-quality detergent or personal care product can only be achieved from a synergy of advanced equipment, scientific formulations, quality raw materials, and strict management. So aiming to help our customers succeed in their businesses, I requested our team to prepare ourselves to be able to provide value on production line equipment, effective formulations, and production management, instead of sorely supplying raw materials.

The Somaliland Project – A Pioneering Endeavor

In September, many thanks to the trust of our esteemed customers Salma Group put in us, our team embarked on our first major turnkey project – designing and implementing a complete liquid detergent production line for them. Salma Group has no experience in manufacturing detergents at all. So they rely on our team to assist them in all aspects to guarantee their success in this project. We are very confident we can accomplish that. This is going to be serial posts. We shall be posting the latest progress we are making on this project. And we have gained the approval from our customer on this.

This complete 5000L per hour capacity liquid detergent production line is designed to produce laundry detergent liquid, dishwashing liquid, hand soap liquid, glass cleaner, and floor cleaner universally. The core of this line is a 5000L homogenizing mixer equipped with a tailor-programmed raw material auto-dosing PLC system based on precision weighing modules and solenoid valves, which ensures high efficiency and dosing accuracy in detergent slurry making.

The following procedures including slurry setting, bottling, capping, labeling, film wrapping, and filming are all done by automatic machines in a streamline.

This project is not just about delivering equipment; it is about understanding and aligning with the client’s vision, resources, and long-term business objectives.

Designing with Precision and Empathy

In designing the production line, our method was comprehensive, carefully evaluating criteria such as output capacity, efficiency of production flow, product quality consistency, regulatory compliance, and the well-being of workers. We aimed to integrate technological innovation with consideration for the human element, creating not only a cutting-edge production facility but also an environment where employees could work comfortably and safely.

The Journey of Equipment – From Preparation to Loading

Over two months, our team worked tirelessly to prepare the machines, tools, and accessories required for the project.

While meticulously crafting the cornerstone of our client’s production capabilities, we at Yeser Chemicals were not content with merely supplying the essentials. Even though, on the agreement signed by both parties, we only listed the staple equipment, such as the water treatment system, raw material feeding system, slurry mixer, settling tanks, filling machine, capping machine, coding machine, labeling machine, and film wrapping & shrinking machine. Our proactive stance guided us to orchestrate the provision of an extensive suite of additional supporting apparatus and tools.

Recognizing the relatively underdeveloped infrastructure in the local community (Somaliland, Africa), and thus the local difficulty in acquiring various necessary tools with ease, our team ensured that all tools and accessories required for the project were comprehensively packaged and provided to the client during this phase.

Production Line Utility Infrastructure

Our client’s production line was designed for seamless operations, necessitating a well-coordinated integration of the utility elements—water, electricity, and air. We provided a comprehensive set of components including pipes, valves, wires, switches, and electrical cabinets to establish a robust utility infrastructure. Furthermore, a sophisticated compressed air system was part of the arrangement to fulfill the production line’s pneumatic requirements, ensuring all operations could function in unison without interruption.

Installation Toolkit Assembly

In anticipation of the intricate setup process, Yeser Chemicals curated a complete toolkit tailored for the installation phase. This included welding machines, welding rods, electric drills, levels, various measuring instruments, and many more. By providing these essential tools, we aimed to facilitate a smooth and efficient assembly of the production line, accounting for every detail in the setup to optimize operational readiness.

Laboratory Equipment and Tools

The laboratory, a central hub for innovation and quality assurance – it’s also a part of regulatory compliance as it’s a mandatory facility requested by the local administration, was equipped with a full array of devices and reagents. This setup is crucial for the extensive testing of liquid detergent products. Our provision of small-scale research instruments enables our client to conduct daily formula modifications and new product development, fostering an environment where innovation is routine.

We anticipated the need for a well-equipped laboratory and provided not only the primary instruments but also secondary accessories that enhance the laboratory’s functionality and regulatory compliance. These include many lab-specific attire such as protective gloves, and white lab coats for the personnel, which are vital for maintaining a sterile environment. We also supplied anti-static chairs and mats, crucial for protecting sensitive equipment and preventing static-related mishaps.

Our attentiveness to these details reflects our commitment to anticipate the laboratory’s multifaceted needs.

Quality Control Tools and Worker Safety Gear

Our comprehensive approach also encompassed the inclusion of precision electronic scales to allow for the random verification of bottle-fill accuracy—a key aspect of quality control in production. We also supplied a full range of personal protective equipment (PPE) such as safety helmets, anti-toxic masks, and protective goggles, prioritizing the safety and well-being of the production staff in their daily operations.

A Little Whispers

All the additional supporting apparatus, tools, and accessories we provided were not specified by the client, nor were they a topic of discussion between our team and the client. These items were not either specifically listed in the agreement and contract signed by both parties. Instead, our team took the initiative to consider all the necessities for both the setup phase and the subsequent daily operations. Without being prompted, we proactively equipped the facility with everything required. This is worry-free package for our customer. They only need to prepare a proper workshop and recruit a team. That’s all. The comprehensive inventory we compiled includes over 200 items, ranging from significant equipment to smaller tools and accessories.

In essence, as we loaded and documented each piece of equipment on November 20th, what we were truly delivering was an ecosystem of production readiness—a comprehensive suite that revolved around Yeser Chemicals’ foundational principles of initiative, precision, and client-focused innovation.

Beyond Installation – Training and Empowerment

The next phase of our journey involves on-site installation, commissioning, and extensive staff training at our client’s facility. This step is crucial as it ensures not just the operational functionality of the production line but also the smooth transfer of knowledge and skills to the client’s team. Developing Standard Operating Procedures (SOPs) for each procedure is a critical part of this process, ensuring the client’s team can manage the production line efficiently and effectively.

Value-Adding Services – Custom Packaging Design and Tailored Formulation Development

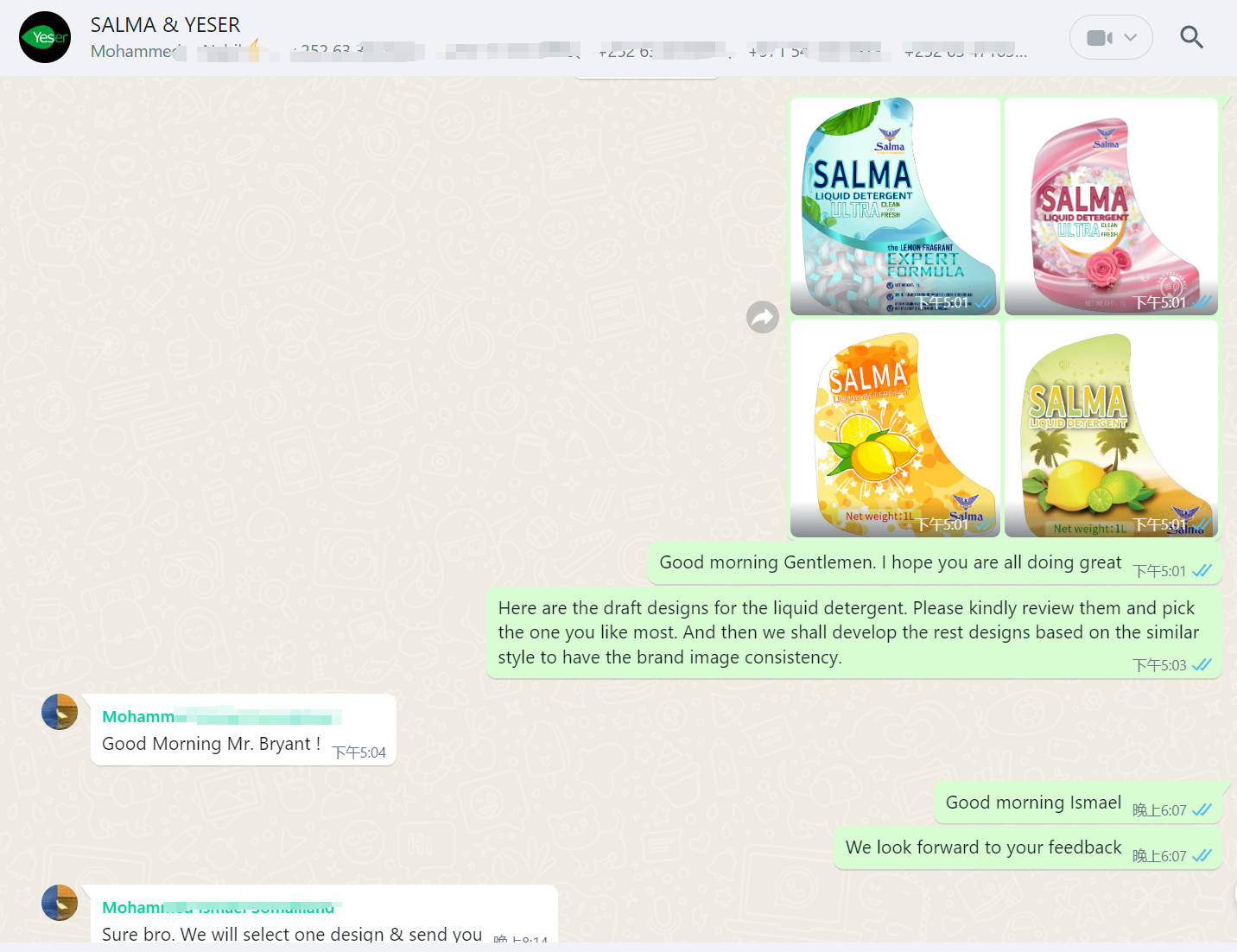

Custom Packaging Design

Yeser Chemicals extends its expertise beyond production setup and raw material supply. We acknowledge the pivotal role that branding and packaging play in differentiating our client’s products in a competitive market. To this end, we invested in crafting unique and appealing packaging designs that resonate with the brand’s identity and values.

Yeser team partners with a creative design team that possesses rich experience in this sector. We collaborate closely with the Somaliland team to ensure that the designs align with their vision and meet their marketing objectives.

Tailored Formulation Development

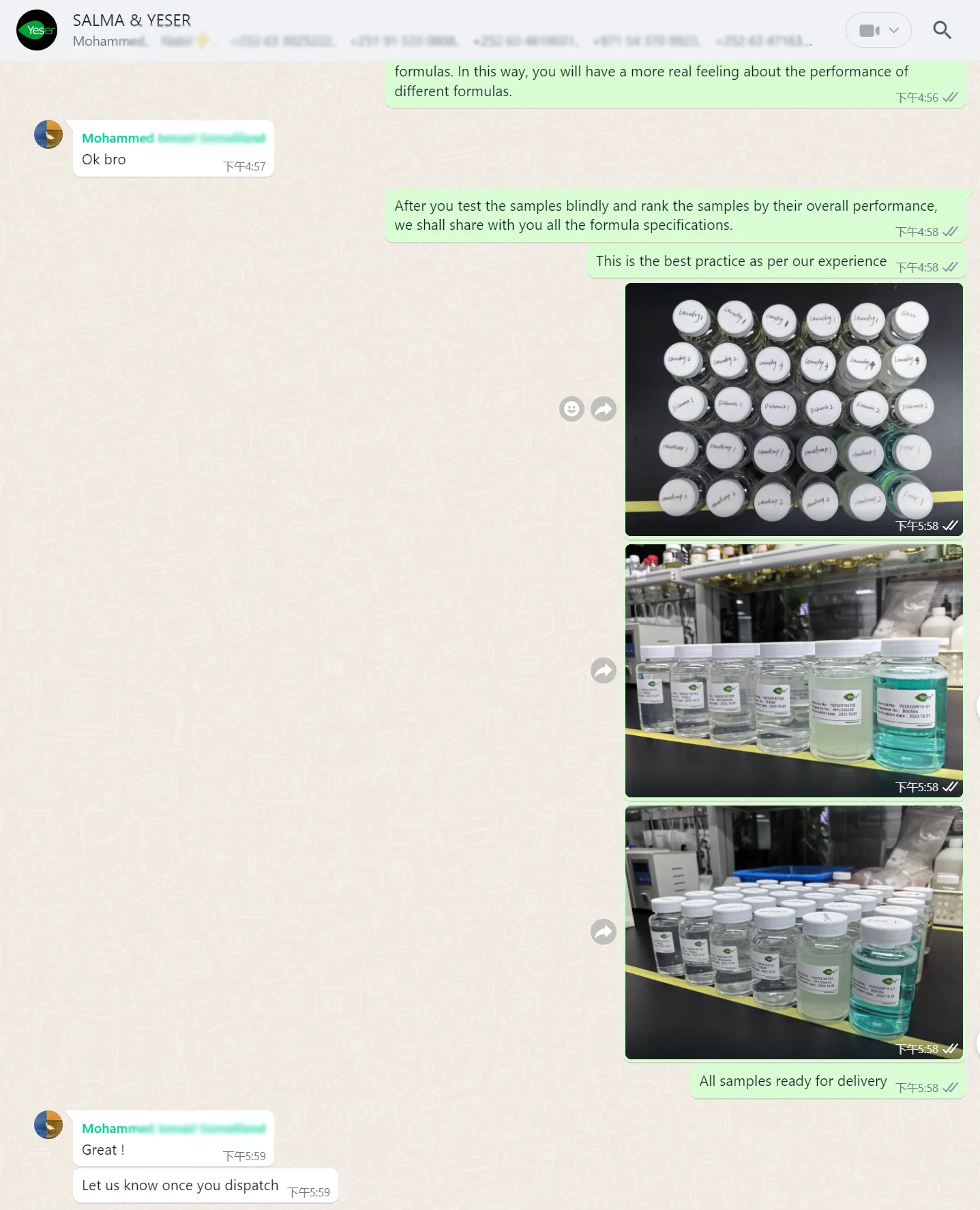

In tandem with our custom design services, we delivered a bespoke approach to product formulation. Recognizing that each market has its unique demands and preferences, Yeser Chemicals developed multiple formula options for various liquid detergents. Our team arranged for samples of these formulations to be sent to the customer without disclosing the specific ingredients, allowing for an unbiased assessment of their performance.

Through this methodology, our client was endowed with the opportunity to conduct ‘blind’ tests and select the optimal formula based on genuine user experience. Yeser Chemicals respects the practicality of real-life usage feedback over theoretical speculation. Post-testing, we committed to providing full formula specifications aligned with the client’s preferences.

A Little Whispers

These value-adding services, documented in direct chat records, illustrate Yeser Chemicals’ commitment to empowering clients not just with high-quality production lines, but also with the tools to make their products stand out in the marketplace. The custom designs and thoughtful formulation services we’ve provided are integral in ensuring our client launches with a strong brand identity and products tailored to market needs.

Wrapping-up – Why We Are the Right Partner For Your Production Line Set-up

As you read here, you have got to know why and how the Yeser team helps our customers establish new production facilities for detergents and personal care products, originally as a dedicated producer and supplier of raw material chemicals. Compared with traditional suppliers of production line equipment, Yeser Chemicals is doing it in an innovative new way that features below benefits to our customers:

A Worry-free Comprehensive Package

At Yeser Chemicals, our philosophy transcends the traditional vendor-client relationship. We view our role as a partner in our clients’ success, offering more than just equipment. Our comprehensive worry-free solutions include everything from core machinery to essential ancillary items; from on-site installation to commissioning, from staff training to technology transferring, ensuring a seamless production line setup and operation. This approach not only facilitates a smoother transition for our clients but also reflects our commitment to their overall success.

The Competitive Edge in Pricing and Quality

- Strategic Pricing Approach

Our competitive pricing model is rooted in a strategy that values long-term benefits over short-term benefits. As a leading provider of raw materials, our primary revenue stream flows from the sale of high-quality ingredients for detergents and personal care products. The provision of production line equipment, then, is an extension of this core business—aimed at facilitating the swift establishment of production for our clients. This accelerates the onset and ensures the longevity of our raw material supply partnership. Consequently, we don’t chase after excessive profits on production line equipment; rather, we view it as an added value service that solidifies the collaborative bond with our clients. This ensures our price competitiveness. - Unwavering Commitment to Quality Equipment

Aligned with our goal of maintaining long-term raw material supply partnerships with our customers, we offer our clients nothing but the finest quality in production line equipment. This commitment is more than just a promise; it’s a fundamental part of our strategy to ensure that our clients’ operations are stable, efficient, and enduring. By prioritizing their operational success, we create a virtuous cycle of raw material demand that benefits both parties in the long term.

Through this two-pronged approach, Yeser Chemicals not only assists clients in the rapid deployment of their production capabilities but also nurtures a stable, enduring supply relationship rooted in mutual benefit and shared success.

Exceptional After-Sales Service and Support

After installing and calibrating the production line equipment, we provide detailed on-site training courses to our customers’ team and develop SOPs for each step of the production process, including quality control procedures in the laboratory. This comprehensive knowledge transfer is pivotal in empowering our clients’ teams to maintain high production standards.

And as we keep supplying raw materials regularly to our customers, it’s convenient for our team to provide long-term after-sales services, including formulation development, replacement of wearing parts, and upgrade or expansion of the production plants.

Unlike most of the equipment suppliers, providing continuous after-sales services is not an empty promise. We are naturally motivated to do so, as we want to keep selling raw materials. The customers definitely won’t buy any material from us if their production stops due to a lack of after-sales services from us.

Real-World Experience and Industry Insight

Our unique industry insight is significantly enhanced by my direct experience of establishing and running DAFA SOAP AND DETERGENT MANUFACTURING PLC in Ethiopia. Our hands-on experience in overseeing the entire process from inception to daily operations provides us with an unmatched understanding of the industry’s needs.

In addition, thanks to our continuous engagement with our clients(mostly detergent and personal care product producers), we have a profound understanding of the real-world industrial manufacturing of detergents and personal care products, including equipment, procedures, and management.

Conclusion

Yeser Chemicals stands out in the market as a provider of comprehensive, sustainable, and innovative solutions. Clients who partner with Yeser Chemicals benefit from enhanced production efficiency and quality assurance. Our turnkey solutions simplify operational setups, allowing our clients to focus on their core business – marketing and sales. Moreover, our long-term partnership approach fosters mutual growth and success, creating lasting relationships in the industry.

Stay Tuned

Stay tuned for our next article, where we will delve into the on-site installation, commissioning, and training phases of the Somaliland project. Discover the depth of our commitment and the breadth of our capabilities as we navigate new horizons in industrial manufacturing. Contact Yeser Chemicals for solutions that go beyond the conventional, into a realm of holistic partnership and progressive innovation.